About Us

Fluidomat Limited, an illustrious ISO 9001:2015, ISO 14001:2015, and OHSAS-ISO 45001:2018 Certified establishment, stands as a preeminent manufacturer of an extensive spectrum of both fixed speed and variable speed fluid couplings, adeptly catering to industrial and automotive propulsions of up to 3500 KW, a legacy spanning back to the year 1971.

Guiding the helm of this venerable institution is Mr. Ashok Jain, a consummate electrical engineer whose comprehensive proficiency traverses the annals of time since the inception of this enterprise in 1971. Mr. Jain stands as a pioneering figure, orchestrating the development and domestic production of fluid couplings, thereby marking an indelible milestone within India’s industrial landscape, all culminating with the momentous introduction of Fluidomat Fluid Couplings in 1971.

Within the corporate ranks of this august institution, one encounters a cadre of personnel whose mettle in their respective domains is peerless, akin to seasoned virtuosos in their chosen fields. The coterie of 275 employees constituting the organization’s collective prowess boasts an enduring association with the Company, a testament to their unwavering dedication and expertise nurtured through the passage of numerous years.

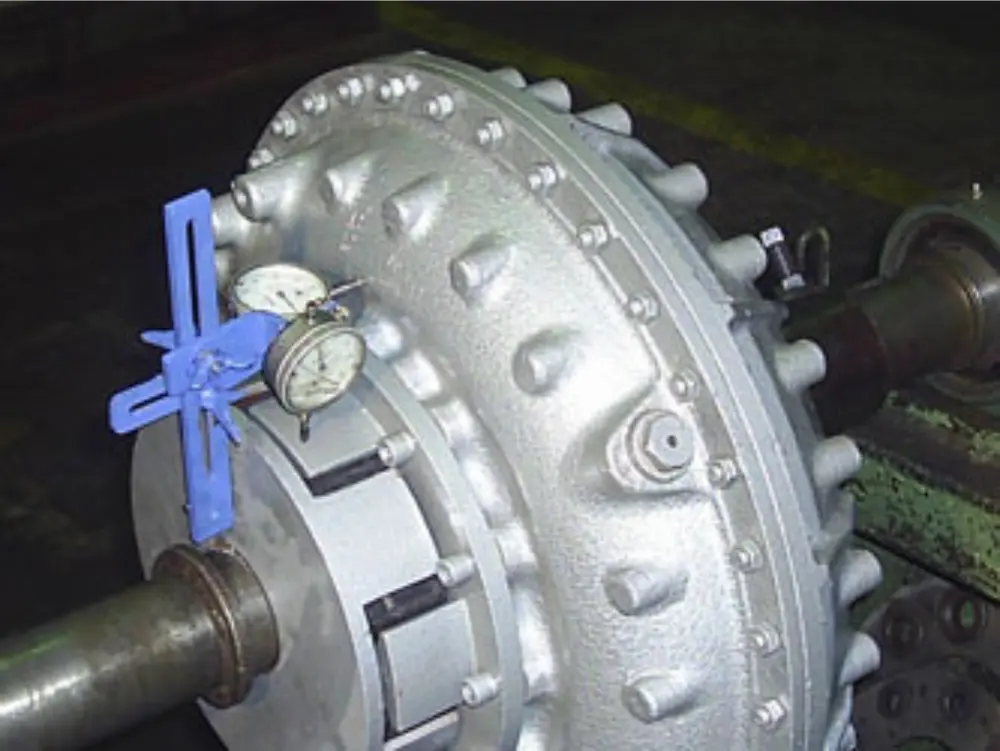

Underpinning this reservoir of technical excellence is a state-of-the-art in-house amalgamation of Non Ferrous and Cast Iron Foundries, proficiently fashioning intricate castings of superlative quality, indispensable for the construction of the Fluid Couplings. These exquisite foundries serve as the crucible wherein craftsmanship transforms raw materials into exquisite, functional artistry.

Located strategically in Dewas, proximate to Indore in Central India, the Fluidomat factory emerges as an oasis of cutting-edge manufacturing, research, and development. It boasts an arsenal of sophisticated facilities spanning the purview of quality control and comprehensive testing mechanisms. These integral components synergize seamlessly to manifest the very essence of quality and consistency, ensuring that the products that bear the Fluidomat insignia are nothing less than impeccable specimens of engineering finesse.

Company Milestones

Traction Type Fluid Couplings

Pulley Type Fluid Couplings

Steel Body Fluid Coupling

Scoop Control Fluid Couplings

Type SM & SMD are Hollow Shaft Fluid Coupling

Steel Body Hollow Shaft Fluid Couplings

Steel Body Hollow Shaft Fluid Couplings

Expanded the range of Fluid Couplings

Twin Fluid Coupling Unit for Hydrodynamic Steering Assistance Unit in different type of tanks

Scoop Control Fluid Coupling Size SC

Radially displaceable Fluid Couplings

Compact Scoop Control fluid Couplings

Traction Type Fluid Couplings to replace Fluidrive FCU Couplings

SM & HF Couplings with extra long delayfil chamber.

SM & HF Couplings with extra long delayfil chamber.

Coupling for Internal Combustion Engine Drive for Stone Crusher and Wood Chipping Application

Coupling for Belt Drive. Couplings can be supplied without pulley and the pulley within specified range.

Scoop Controlled Fluid Couplings Size 1330

Scoop Controlled Fluid Coupling for Boiler Feed Pumps of 3000/3600 RPM.

Drain Type Fluid Coupling for Internal Combustion Engines.

Elevating Standards in Quality Assurance

Quality First, Always

Uncompromising dedication to ISO 9001:2015 standards in every coupling.

Evolved Engineering Since 1971

Pioneering fluid couplings with cutting-edge tech and application expertise.

Your Assurance in Every Turn

Meticulous design, manufacture, and support for satisfaction-guaranteed solutions.

Innovation, Always On

Fluidomat's fluid couplings – where technology meets reliability seamlessly.