Drain Nozzle Type Fluid Coupling

Previous

Next

- No-load engine startup during declutching

- Simple operation via the solenoid valve

- Absorbs shocks and dampens vibrations

- Enables smooth machine startup

- Prevents belt slippage

- Robust and low-maintenance

- Radially Displaceable fluid couplings with resilient driving plate on.

- Input side and metallic disc flexible coupling on output side.

Construction:

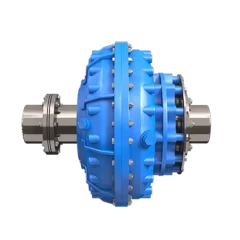

- Primary casing houses Impeller and Rotor

- Fixed Scoop Tube collects oil from the working circuit

- Shafts connect Impeller and Rotor to motor and driven machine shafts

- Bearings support the shafts

- Robust, self-supported housing

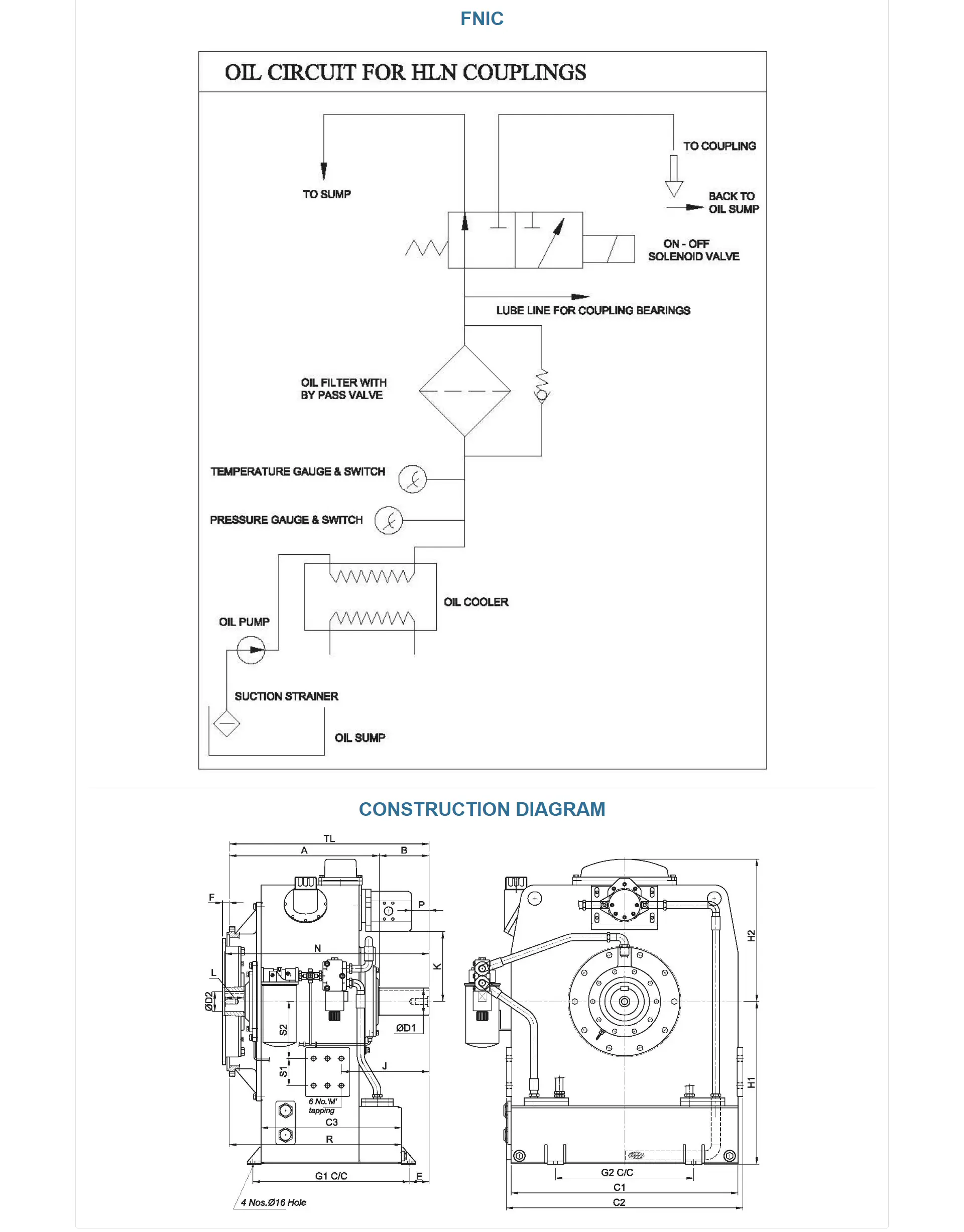

- Motor-driven oil pump circulates working oil

- Solenoid valves and non-return valves control oil levels

- Lube line feeds oil to bearings continuously

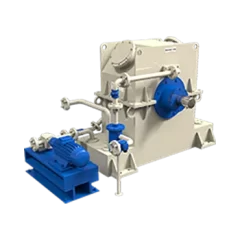

- Ideal for startup and acceleration in Belt and Pipe Conveyor systems, underground mines, surface installations, crushers, mills, and more

- Oil circulates through the working circuit

- Leak-off nozzle drains oil into the secondary casing

- Solenoid valves adjust oil levels between 0% to 100%

- Declutching empties the circuit via solenoid valves

- Electronic control adjusts oil levels during acceleration

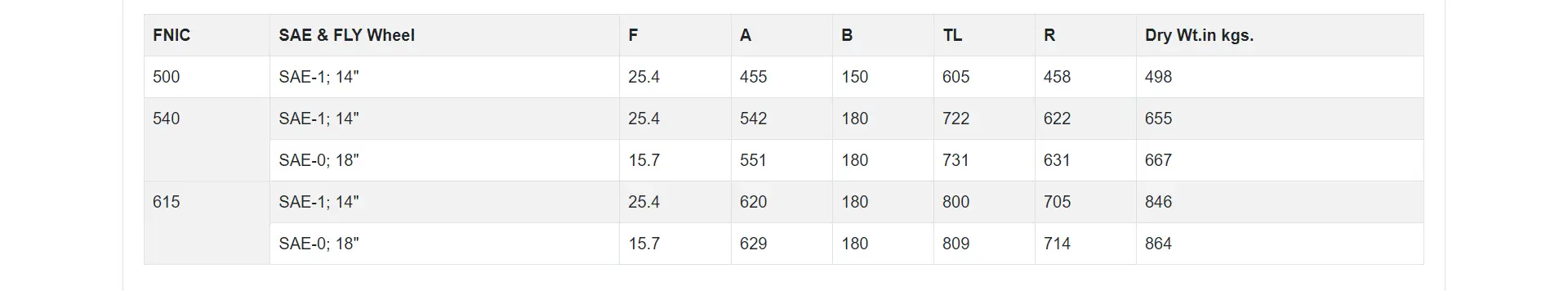

Rating Table of FNIC Combustion Engine Drive

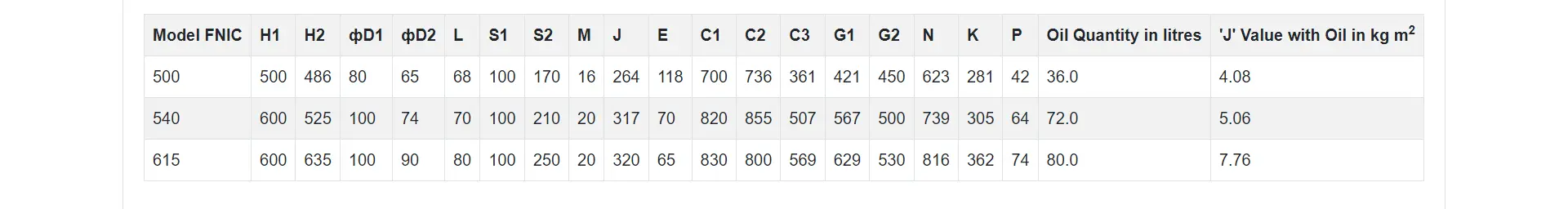

Dimension Table of FNIC Combustion Engine Drive

Oil Circuit for FNIC Coupling