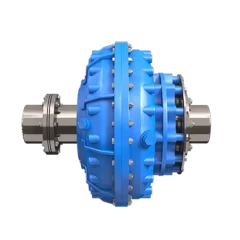

Fixed / Constant Speed Couplings (Steel Body) Type CBSF

- Robust steel body constant fill fluid couplings with hollow and flexible shaft ends

- Available with or without delayfil chamber

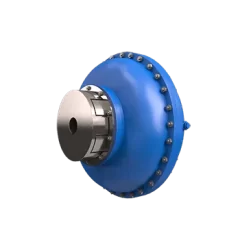

- Radially displaceable execution with metallic disc couplings on both ends (Type WF HF & CBSF HF)

- Suitable for underground or opencast mines and areas prohibiting aluminum use

- Water-oil emulsion or mineral oil operation

- Adjustable torque capacity: CBSF (180% to 270%), CBSF DF (150% to 270%)

Type CBSF: are steel body constant fil fluid couplings with hollow shaft execution on one end and flexible coupling on the other end for respective shaft connections. They are available with delayfil chamber type CBSF DF and without delayfil type CBSF. Also available in Radially Displaceable execution having metallic disc flexible coupling on both ends. Type WF HF & CBSF HF are radially displaceable fluid couplings with metallic disc flexible coupling on both input and output ends. These metallic disc couplings do not require any lubrication and require least maintenance. The weight of fluid coupling is shared by motor and driven machine shaft thus reducing weight reaction on gear box shafts which are of small diameters in modern designs.

- Water – Oil emulsion as per HFB classification of European Mines safety commission.

- Mineral oil as operating fluid.

- Maximum torque transmitting capacity is adjustable between 180% to 270 % for CBSF and 150 to 270% CBSF DF delayfil couplings.

- These steel body fluid couplings are of extremely robust construction. They are ideal for use in underground or opencast mines or other sites where use of aluminum is prohibited or where robust construction is necessary with simplicity of construction. These steel body fluid couplings are being manufactured by us since 1976 and are very well proven on various mining and surface applications.

They offer all the advantages and performance characteristics of any other aluminium body Fluidomat Fluid Couplings.

- Virtually no load start and run up of motor and utilization of motor peak torque for load acceleration.

- Smooth and controlled acceleration of driven machine.

- Quick decay of motor starting current kick.

- Adjustable starting characteristics and load limiting.

- Dampening of shock loads, torsional fluctuations and vibrations.

Connected Flexible Coupling

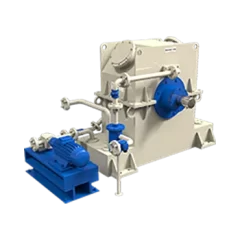

Rating Table SF

Dimension Table CBSF HF, CBSF HFD & CBHFDX

CBSF Type Drawing