Leak off Nozzle Type Fluid Coupling

- Controlled startup and smooth acceleration for large drive motors

- No-load motor startup reduces starting current

- Wear-free power transmission

- Gradual breakaway torque

- Clutching and declutching with the motor running

- Dampening of shocks and vibrations

- Suitable for electronic control and multi-drives

- Cooling during standstill

- Compatible with various couplings

- Robust, low maintenance design

- Radially Displaceable fluid couplings with resilient driving plate on.

- Input side and metallic disc flexible coupling on output side.

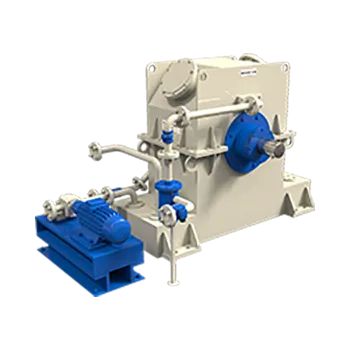

Construction:

- Primary casing houses Impeller and Rotor

- Fixed Scoop Tube collects oil from the working circuit

- Shafts connect Impeller and Rotor to motor and driven machine shafts

- Bearings support the shafts

- Robust, self-supported housing

- Motor-driven oil pump circulates working oil

- Solenoid valves and non-return valves control oil levels

- Lube line feeds oil to bearings continuously

- Ideal for startup and acceleration in Belt and Pipe Conveyor systems, underground mines, surface installations, crushers, mills, and more

- Oil circulates through the working circuit

- Leak-off nozzle drains oil into the secondary casing

- Solenoid valves adjust oil levels between 0% to 100%

- Declutching empties the circuit via solenoid valves

- Electronic control adjusts oil levels during acceleration

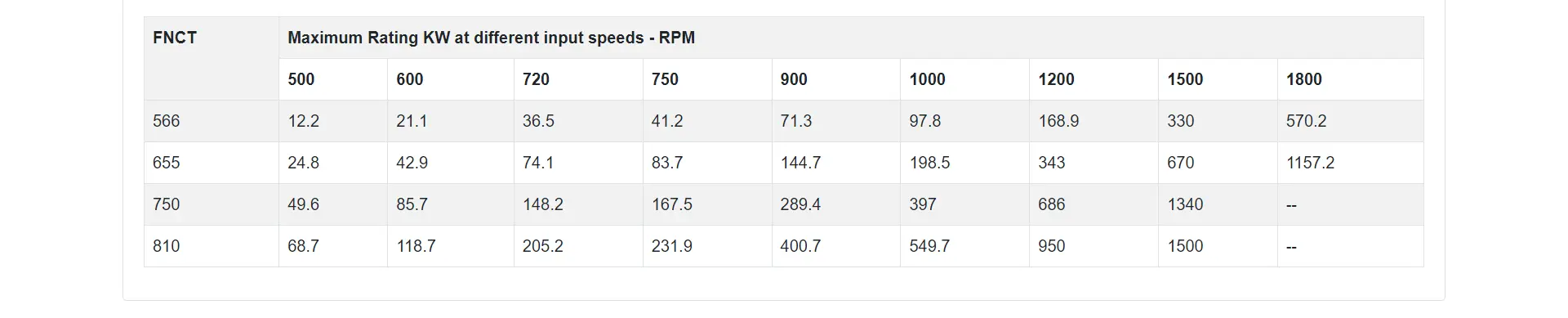

Maximum Rating KW at Different Input Speeds - RPM